| Phoenix-S

Heater Retrofit Kit

Kit consists

of:

1ea. Silicone

Rubber Heater with built in fixed thermostat

1ea. Mounting bracket

with mounting screws.

1ea. Control Power ON/OFF

Switch

1ea. Fuse Holder with

2 ½ AMP fuse (120V); 1 ½ AMP fuse (240V)

1ea.Wire attachment

hardware.

1ea. Protective Sleeve

Required

Materials:

A small amount

of laundry detergent and water.

Isopropyl Alcohol

Clean Wipes

The heater

is designed to heat the oil in the tank to a control set point to vary

the flow and viscosity of the oil being applied to each lane.

|

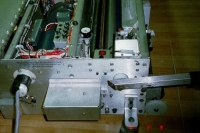

Position

Heater on the tank

|

|

|

|

|

|

Attach

bracket with 8-32 Screws

|

|

- Check the parts to ensure

completeness

- Unplug the machine

- Position the machine to

expose the oil tank.

- Clean the oil tank. Use

a mild solution of laundry detergent to clean the oil tank and remove

any surface contamination. Be sure to rinse the detergent off with

clean moist wipes, allow to air dry. Using a clean lint free wipe and the isopropyl

alcohol, clean the surface of the oil tank and allow to air dry.

- Noting the direction of

the wires on the heater, position the heater as shown in drawing.

(Figure 2A). Remove the adhesive

backing carefully and attach the heater to the oil tank, centering

the heater with the tank.

- Slide the protective

sleeve over the heater wires positioning it close to the heater, then

pass the wires through to the electrical compartment. Be sure to keep

the wires away from all moving belts or parts.

- Locate position to mount

the power module bracket. Attach loosely.

- Locate the main power

line in from socket. The L1 (Red wire).

- Run the heater power line

along the wire bundle to the power module, one wire from the heater

attaches to the male stab pin at the rear of the lighted power on/off

switch. The remaining heater

wire is attached to the short white wire, along with the length of

supplied white extension wire (Neutral).

- Route the heater wires

neatly to the power on/off module. Leaving a short service loop, trim

wires to fit if necessary. Strip the end of the first heater wire and

terminate with an insulated female crimp push terminal (supplied).

- Push the terminal firmly

onto the male tab at the rear of the power on/off rocker switch.

- Locate the Line Power

Inlet, there should be a red wire (L1), a white wire (N) and a green

wire (ground) The red fused wire from the control assembly should

be attached/spliced to the incoming L1 wire prior to the circuit breaker,

this may be accomplished by utilizing the supplied wiring connectors

or by attaching directly to the terminal block TB-1 located above

the power receptacle.

- Check all connections

to ensure to ensure proper contact.

- Attach the controller-mounting

bracket to the frame securely.

- Check to ensure that wires

are clear of all moving parts prior to securing the wires to the wiring

bundle.

- Plug in the machine.

- Power Up the unit, energize

the heater with the on/off switch.

- Confirm that the heater

is energized; the power on/off switch should be lighted, indicating

that the heater is energized. The heater temperature is self-regulating

and should provide a constant oil tank temperature.

For best results do not overfill tank. Check oil level before

each cleaning cycle.

- After all tests are complete

and the wiring is firmly attached, power off the unit.

- Close all compartments

and the machine should be ready for use.

|