| |

Online

Industrial Process Equipment |

|

High

Quality Products - Long-Term Reliability |

|

|

|

Super

Air Knife™ |

|

|

Quiet, hard-hitting curtain

of air for blowoff, cleaning, drying and cooling.

EXAIR's Super Air Knife is a new

generation of air knife that dramatically reduces compressed air

usage and noise when compared to other blowoffs. The Super Air Knife

offers a more efficient way to clean dry or cool parts, webs or

conveyors. It delivers a balanced sheet of laminar airflow

across the entire length with hard-hitting force. Noisy blowoffs

become a whisper when replaced with this new, compact design.

Even at high pressures of 80 PSIG (5.5 BAR), sound level is surprisingly

quiet at 70 dBA for most applications! Amplification rations

(entrained air to compressed air) of 40:1 are produced. The

Super Air Knife meets OSHA dead-ended pressure and noise requirements

Printable PDF File Printable PDF File

|

|

- Part drying

after wash

- Sheet

cleaning in strip mills

- Conveyor

cleaning

- Part

or component cooling

- Web drying

or cleaning

- Environmental

separation

- Pre-paint

blowoff

|

- Quiet

- 70dBA for most applications

- Minimal

air consumption

- 40:1 air

amplification

- Balanced

airflow across entire length

- No moving

parts

- Aluminum

or stainless steel

- Compressed

air inlets on ends and bottom

|

- Compact,

rugged easy to install

- Recessed

hardware for easy mounting

- Stock

lengths 3" to 42"

(107cm)

- Special

lengths available

- Unlimited

system lengths of airflow

- Variable

force and flow

- Maintenance

free

|

|

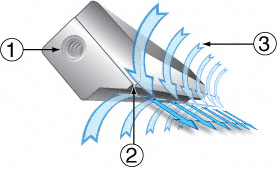

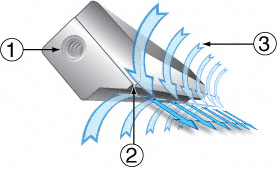

Compressed air

flows through the inlet (1) into the plenum

chamber of the Super Air Knife. Multiple channels inside direct

the flow to a precise, slotted orifice. As the primary airflow

exits the thin slotted nozzle (2), it creates a uniform sheet

of air across the entire length that immediately pulls in

surrounding room air (3). Velocity loss is minimized by entraining

the room air into the primary airstream. The result is a well

defined sheet of laminar airflow with hard-hitting force and

minimal wind shear.

Most plants try to limit compressed air usage and

eliminate blowoffs that exceed OSHA noise level requirements.

The new Super Air Knife has been engineered to deliver a uniform,

high velocity, high volume sheet of air with low noise and minimal

air consumption. As shown by the chart, it's easy to see

why the Super Air Knife is the best choice for blowoff, cooling

and drying applications. The Super Air Knife reduces compressed

air usage by 15% when compared to EXAIR's Standard Air Knife or

by 63% when compared to a drilled pipe! Noise level of the Super

Air Knife is 6 times quieter than the Standard Air Knife and 11

times quieter than the drilled pipe! |

|

|

Super Air Knife (top), Standard Air Knife

(middle) and drilled pipe (bottom).

|

|

Specifications

The Super Air Knife is available

in nine standard lengths of 3", 6", 12", 18",

24", 30", 36" , 42" and 48" (7.5,

15, 30, 46, 61, 76, 91, 107 and 122cm) in Aluminum, and eight standard

lengths of 3", 6", 12", 18", 24", 30",

36" and 42" (7.5, 15, 30, 46, 61, 76, 91 and 107cm) in

Stainless Steel. Special lengths are available. Any number

of Super Air Knives may be installed across a given area.

Filtration:

The use of

clean air is essential. Kits include an automatic drain filter with

a 5 micron filter element that is sized properly for flow.

Materials of Construction:

The Super Air

Knife is available in either aluminum or stainless steel construction.

Mounting:

The Super

Air Knife can be supported by the compressed air pipe. Tapped holes

(1/4-20) on the bottom are also provided.

Regulation:

A pressure regulator

on the compressed air supply provides infinite control of flow,

force and air consumption. Kits include a pressure regulator that

is sized properly for flow.

Shim Sets:

The compressed

air exhausts through a gap which is set with a shim positioned between

the cap and the body of the Super Air Knife. Force and flow through

the Super Air Knife may be easily increased by adding shims to open

the gap. Kits include a shim set (three additional shims). |

| Compare

Blowoffs |

|

Type of Blowoff

|

Air

Consumption |

Sound

Level |

| Model

# |

Description

|

SCFM |

SLPM |

dBA |

| 110018 |

18"

(46cm)

Super Air Knife |

52 |

1329 |

71 |

| 2018 |

18"

(46cm)

Std. Air Knife |

61 |

2234 |

87 |

| N/A |

18"

(46cm)

drilled pipe* |

141 |

3996 |

92 |

*

drilled pipe has (37) 1/16" (1.59mm)

holes on 0.5" (13mm) centers |

The

Super Air Knife uses 63% less air and is 11 time quieter than drilled

pipe! |

|

|

| Dimensions

- Aluminum Super Air Knife |

Dimensions

- Stainless Steel Super Air Knife |

| |

|

|