|

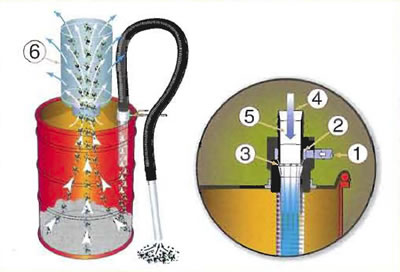

Vacuums chips directly into a 55 gallon drum - with no moving parts!

The Chip Vac picks up dry or wet chips and delivers

them directly to an ordinary 55 gallon (40 imperial gallon) drum.

Chip Vac is used to clean chips from fixtures, floors and work surfaces

of machining centers, lathes, saws, mills and other industrial equipment.

- No

moving parts

- Low

cost

- Chips

go directly into a drum

- 50%

quieter than electric vacs

|

- No

motors to clog or wear out

- No

electricity

- Dust

free operation

- Powerful

cyclonic action

|

The compressed air operated Chip Vac is an industrial

duty vacuum designed specifically for vacuuming chips. It creates

a powerful cyclonic action that vacuums metal, wood or plastic chips

into a 55 gallon drum. Dusty materials such as absorbents are trapped

by the 0.1 micron filter bag to keep the surrounding air clean. Chip Vac's lever lock drum lid fits an ordinary

open top 55 gallon drum. In less than a minute, the Chip Vac can

be removed and easily placed onto another drum to keep different

materials separate for recycling. Constant heavy lifting and dumping

of vacuum cleaner tanks is eliminated since all chips are vacuumed

directly to the 55 gallon drum.

Electrically operated "all

purpose" vacuums aren't designed for use in industrial environments.

As a result, motors wear out quickly and impellers clog. Chip Vac

has no moving parts to wear out or break which ensures long life.

Sound level is half that of electric vacuums. |

|

| The Chip Vac removes abrasive stainless steel chips

from a vertical machining center |

|

| Room air remains dust free as the Chip Vac removes

dusty absorbent. |

|

Air consumption has been minimized by using the appropriate amount

of air required for vacuuming chips. The Chip Vac System can

be used with an open head steel, fiber or plastic drum that is in

good condition (ANSI Standard #MH2-1997). To prevent material contamination,

a poly drum liner can be inserted into the drum. |