|

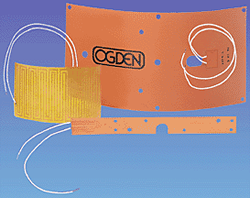

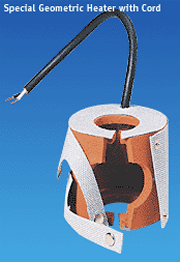

Silicone Rubber Flexible Heaters were originally designed for the aerospace and defense industries. Common were such applications as maintaining constant temperatures in the instrumentation of aircraft, satellites, navigation, guidance and radar equipment. The versatility of this product has since been widely recognized as thousands of uses have been discovered. Flexible heaters are regularly specified because of their light weight, thin profile, low thermal mass and flexibility. The abilities to provide an infinite array of patterns and concentrations of heat are additional characteristics. Complex shapes, contours and three-dimensional patterns are possible. Many mounting methods are available for the application of Flexible Heaters. Computer generated specifications and state-of-the-art manufacturing technologies produce the most effective Flexible Heater performance possible.

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

RESISTANCE ELEMENTS Wire Wound Element: A fine gauge resistance wire is spiralled around a fiberglass core. The element is placed in a specifically designed pattern and vulcanized to either a silicone rubber or neoprene substrate. Advantages versus etched foil elements are: Physical strength; flexibility; smaller production quantity; conforms well to small radius bends and larger possible sizes. |

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Etched Foil Element: The manufacturing process of etched foil elements is adapted from the production of printed circuit boards. A nickel resistance alloy foil is acid etched to the specific pattern, then vulcanized to the sheath material. Advantages versus wire wound are: Higher watt densities; greater area coverage of element over heater sheath; higher production quantities and complex heat distribution. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

SILICONE RUBBER HEATERS Silicone Rubber Heaters are rugged, moisture and chemically resistant and are easily bonded or cemented to heat sinks or other parts to be heated. Temperatures from -80 to 455°F (-62 to 235°C) and up to 20 watts per square inch are regularly supplied. The thin profile transfers heat quickly because the actual resistance element is so close to the heated part. Silicone Rubber Heaters can he insulated with silicone sponge rubber bonded to one side. Another way to lower radiated and convected heat losses is to apply an aluminized surface to the heater back. Very little is added to the overall thickness. Integral adjustable or preset thermostats, thermocouples, RTD's, thermistors or thermofuses can be included. |

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

TERMINATIONS Silicone leads for temperatures to 390°F (200°C) are most often supplied, but many other types are available. The leads are attached to the element within the transition area and covered with a 1" x 1" (typical) patch of the same material as the sheath. The entire lead transition assembly is then vulcanized to the heater sheath. Leads can be arranged to exit at about any point on the element sheath, corner, or from an external tab. Neoprene, silicone and Teflon leads along with HPN cord and plug sets can be supplied.

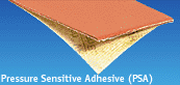

MOUNTING METHODS Pressure Sensitive Adhesive (PSA) is a factory applied material for bonding Flexible Heaters to a flat, smooth surface. A peel-away protective backing allows simple field installation. The maximum element temperature for PSA use is 300°F (150°C) continuous, 455°F (235°C) intermittent, at no more than 5 watts per square inch. Heaters with PSA should be stored no more than 6 months before installation. Factory Vulcanizing provides excellent heat transfer from the heater element to the customer part. Strong, free of air gaps and with the longest possible heater life are advantages of Factory Vulcanizing. Maximum sheath temperature is 455°F (235°C). For field applied adhesives, an RTV Room Temperature Vulcanizing Adhesive or Contact Cement are available. Also available for Flexible Heaters are several mechanical field mounting devices such as hooks and laces, grommets and laces, spring loaded latches, snaps or velcro.

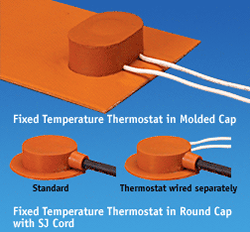

THERMOSTATS AND SENSORS Many other thermostat temperature ranges and ratings are available than what is shown. A minimum order quantity may apply. Thermostats separate from heater and ambient sensing thermostats in several temperature ranges are also available. Thermocouples, RTD's, thermistors and thermal fuses are normally mounted under a silicone rubber cap which is vulcanized to the heater sheath. The position can be anywhere on the heater surface. Thermostats are typically integral to the heater, encapsulated in silicone rubber and mounted in a heated area. The position is determined based upon application considerations, prototyping and testing. Thermostats rated at 125V/15A, 250V/10A. Thermostat can be wired separately when rating is exceeded. Typically, the differential between the on and off position is 30°F. Tolerance: ± 5°F open ± 8°F closed

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

SILICONE RUBBER ENCLOSURE HEATERS A wire wound Silicone Rubber Heater with ambient sensing thermostat and aluminum mounting plate are designed to prevent humidity and moisture accumulation in electrical and mechanical enclosures. Enclosure heaters can be supplied with thermostat separate from heater or without mounting plate. With built-in ambient sensing thermostat, the minimum width is 2". Available lengths are from 5" to 40" at 5 watts/square inch. Aluminum mounting plate is 1/2" wider than heater. Mounting slots are conveniently located. The suggested mounting is vertical with the thermostat at the bottom as shown. Available thermostat setting is 40°F (4°C) 40°/55°F (4°C/13°C). Consult Ogden for other settings available. Minimum quantity may apply. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Click Here to Determine Wattage Requirements for Enclosure Heaters | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Surface

Temperature versus Time for Silicone Rubber Heaters Illustrated is the surface temperature of a standard Silicone Rubber Heater, .055" thick without insulation at several watt densities. The heater is suspended vertically in 70°F (20°C) still air. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Maximum

Watt Density Etched foil elements can be designed at higher watt densities based upon application considerations. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

SPECIFICATIONS The area where leads are attached

adds additional thickness depending upon gauge wire used and type.

Consult Ogden. Composite Bonding Processes and other applications may require special heat pattern or uniformity. Heat Mapping Certification is available as an option. Underwriter's Laboratory, CSA and CE recognition or listing apply to most configurations. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Ordering Information: Specify: Catalog Number, if available, or; |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Important Notice: By purchasing products from this Site, you acknowledge and agree that you have read and accept the Terms and Conditions of this online store. For more information email us at: info@iprocessmart.com |

| Copyright © 2009 iProcesSmart™.com |